| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | chuangwei |

| Model Number : | CWVC-6 |

| Certification : | CE |

| Price : | Negotiable |

| Payment Terms : | T/T, Western Union, L/C |

| Supply Ability : | 260 sets per month |

| Delivery Time : | 1-3 work days |

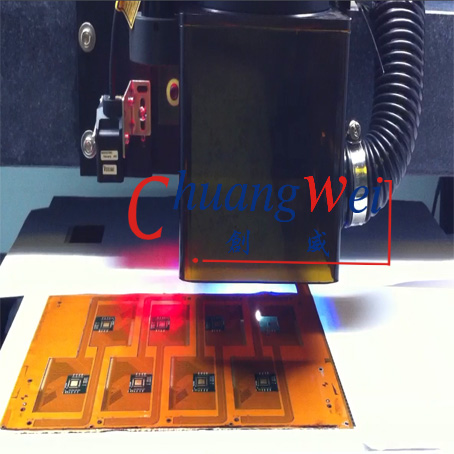

High Precision Pcb Depaneling Equipment All Solid State UV Laser 355nm Industrial PCB Laser Depaneling

PCB depaneling (singulation) laser machines and systems have been gaining popularity over recent years. Mechanical depanaling/singulation is done with routing, die cutting, and dicing saw methods. However, as the boards get smaller, thinner, flexible, and more sophisticated, those methods produce even more exaggerated mechanical stress to the parts. Large boards with heavy substrates absorb these stresses better, while these methods used on ever-shrinking and complex boards can result in breakage. This brings lower throughput, along with the added costs of tooling and waste removal associated with mechanical methods.

Increasingly, flexible circuits are found in the PCB industry, and they also present challenges to the old methods. Delicate systems reside on these boards and non-laser methods struggle to cut them without damaging the sensitive circuitry. A non-contact depaneling method is required and lasers provide a highly precise way of singulation without any risk of harming them, regardless of substrate.

Challenges of Depaneling Routing

Specification

| Laser | Q-Switched diode-pumped all solid-state UV laser |

| Laser Wavelength | 355nm |

| Laser Power | 10W/12W/15W/17W@30KHz |

| Positioning Precision of Worktable of Linear Motor | ±2μm |

| Repetition Precision of Worktable of Linear Motor | ±1μm |

| Effective Working Field | 300mmX300mm(Customizable) |

| Laser Scanning Speed | 2500mm/s (max) |

| Galvanometer Working Field Per One Process | 40mmх40mm |

|